BLOG

RECENT UPDATES

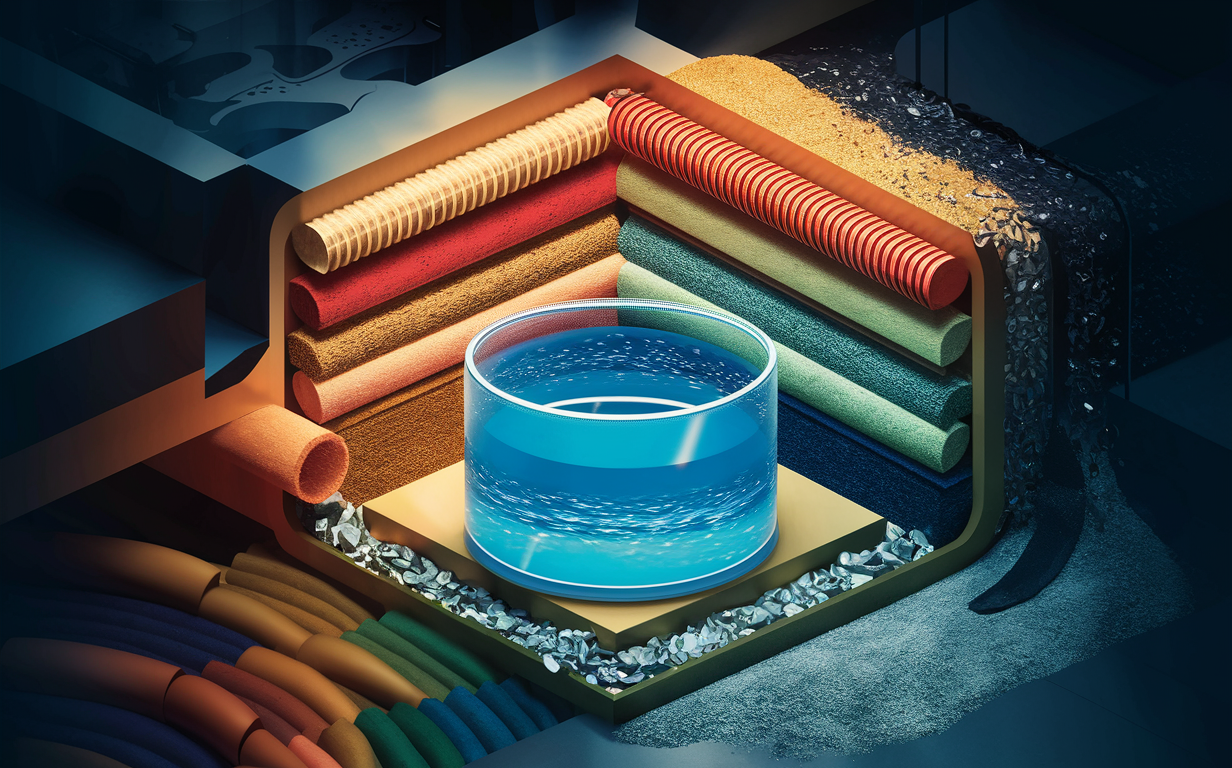

Ensuring Clean Water: Understanding Sediment and Particulate Filtration Systems

When it comes to maintaining clean and safe water for commercial applications, sediment and particulate filtration systems play an essential role. These systems are crucial for removing physical impurities from water, making it suitable for various industrial, commercial, and even residential uses.

- Sediment and particulate filtration systems remove physical impurities like dirt, sand, and rust from water.

- These systems are vital for protecting plumbing, equipment, and ensuring clean water for various uses.

- Businesses benefit significantly from using these systems due to the improved longevity and efficiency of their water-dependent processes.

What are Sediment and Particulate Filtration Systems?

Sediment and particulate filtration systems are designed to eliminate suspended solids, such as dirt, sand, silt, and rust, from water. These systems use various types of filters to capture and remove these impurities, ensuring that the water is clear and safe for use.

How Do These Systems Work?

The process involves water passing through one or more filters that trap and hold sediments. Depending on the system, filters can range from coarse sand filters to fine membrane filters, each targeting different sizes of particles.

Importance of These Systems in Commercial Settings

In commercial environments, clean water is not just a luxury but a necessity. Whether it's for manufacturing processes, food and beverage production, or maintaining a clean environment, sediment and particulate filters are indispensable.

Benefits of Using Sediment and Particulate Filtration Systems

- Improved Water Quality: Removes visible impurities, improving the overall quality of water.

- Protects Equipment: Prevents clogging and damage to industrial machinery.

- Enhanced Efficiency: Ensures smooth operation of processes that rely on clean water.

- Cost Savings: Reduces maintenance costs and prolongs the lifespan of equipment.

Types of Sediment and Particulate Filters

- Spun Filters: Made from polypropylene, ideal for capturing larger particles.

- Pleated Filters: More surface area for trapping sediments, suitable for finer particles.

- String-Wound Filters: Effective for various particle sizes.

- Membrane Filters: Used for ultra-fine filtration.

Table 1: Comparison of Different Filter Types

| Filter Type | Material | Particle Size Captured | Ideal Use Case |

|---|---|---|---|

| Spun Filters | Polypropylene | Large particles | Pre-filtration |

| Pleated Filters | Polyester | Medium to large | Industrial applications |

| String-Wound | Cotton or Rayon | Various sizes | General-purpose filtration |

| Membrane Filters | Various Polymers | Ultra-fine particles | High-purity water applications |

Real-Life Applications in Commercial Settings

Manufacturing Industry

In manufacturing, clean water is essential for cooling systems, product washing, and even in the production process. Sediment and particulate filters ensure that the water used is free from contaminants that could compromise product quality or damage machinery.

Food and Beverage Industry

For any business involved in food and beverage production, maintaining high water quality is non-negotiable. Filters remove contaminants that could affect taste, safety, and regulatory compliance.

Hospitality Sector

Hotels and restaurants benefit from clean water for both guest use and operational purposes. These filters ensure that water is safe for consumption and use in kitchens and laundry facilities.

Maintenance and Replacement

Regular maintenance and timely replacement of filters are crucial for the optimal performance of sediment and particulate filtration systems. Depending on the water quality and usage, filters should be changed every few months to a year.

Maintenance Schedule for Different Filter Types

| Filter Type | Typical Lifespan | Maintenance Frequency |

|---|---|---|

| Spun Filters | 3-6 months | Every 3 months |

| Pleated Filters | 6-12 months | Every 6 months |

| String-Wound | 4-6 months | Every 4 months |

| Membrane Filters | 1-2 years | Annually |

Frequently Asked Questions About Sediment and Particulate Filtration Systems

What contaminants do these systems remove?

These systems primarily remove physical contaminants such as dirt, sand, silt, and rust. They do not typically remove dissolved substances like chemicals or biological contaminants.

Are these systems expensive to install?

The cost varies depending on the type of system and the complexity of installation. However, the long-term benefits and cost savings from reduced maintenance and equipment damage often outweigh the initial investment.

How often should filters be replaced?

Filter replacement depends on the water quality and usage. Generally, filters should be replaced every 3-12 months.

Can these systems be used with other filtration methods?

Yes, sediment and particulate filters can be used in conjunction with other filtration systems like carbon filters or reverse osmosis systems for comprehensive water treatment.

What size filter should I choose?

The choice of filter size depends on the specific contaminants present and the water flow rate required. It's essential to have your water tested to determine the best filter for your needs.

Maximizing the Efficiency of Sediment and Particulate Filters

To get the most out of these filtration systems, consider the following tips:

- Regular Maintenance: Keep up with the recommended maintenance schedule to ensure filters are working effectively.

- Proper Installation: Ensure that filters are properly installed to avoid leaks and inefficiencies.

- Monitor Water Quality: Regularly test water quality to detect any changes and address issues promptly.

- Use Pre-Filters: In areas with high sediment levels, using a pre-filter can help extend the life of the main filter.

Benefits of Regular Filter Maintenance

- Consistent water quality

- Extended filter lifespan

- Prevention of equipment damage

- Reduced operational costs

- Improved system efficiency

The Role of Technology in Filtration Systems

Advancements in filtration technology have led to the development of more efficient and durable filters. Innovations like smart sensors and automated maintenance alerts are making it easier for businesses to maintain their filtration systems.

Smart Filtration Systems

Some modern filtration systems come equipped with smart technology that monitors water quality and filter performance. These systems can alert users when it's time to replace filters or when there are issues that need attention.

Automated Maintenance

Automated systems reduce the need for manual intervention, ensuring that filters are maintained and replaced promptly, which helps in maintaining consistent water quality.

Environmental Impact

Using sediment and particulate filtration systems also has a positive environmental impact. By ensuring that water used in commercial applications is clean, these systems help reduce the discharge of contaminants into the environment.

Reducing Waste

High-quality filters reduce the need for frequent replacements, minimizing waste. Additionally, some filters are designed to be recyclable, further reducing their environmental footprint.

Conclusion

Investing in sediment and particulate filtration systems is essential for any business that relies on clean water. These systems not only improve water quality but also protect equipment, enhance efficiency, and offer significant cost savings. Regular maintenance and the use of advanced technology can further enhance the benefits of these systems, making them an indispensable part of modern commercial operations.

By understanding and implementing these filtration systems, businesses can ensure a consistent supply of clean water, contributing to both operational efficiency and environmental sustainability.

Contact Us

Address: 2755 Vista Pkwy Ste I5

West Palm Beach, FL 33411-2738

Email: simplewaterinc@gmail.com

Phone: (561)-309-6270

Time: Mon–Fri: 8AM–6PM | Sat: 9–5 | Sun: Closed

Follow us

Get a Quote

©2023 Simple Water Service. Do not copy. All rights reserved.